founder

Welding

Fab Werks, Inc.

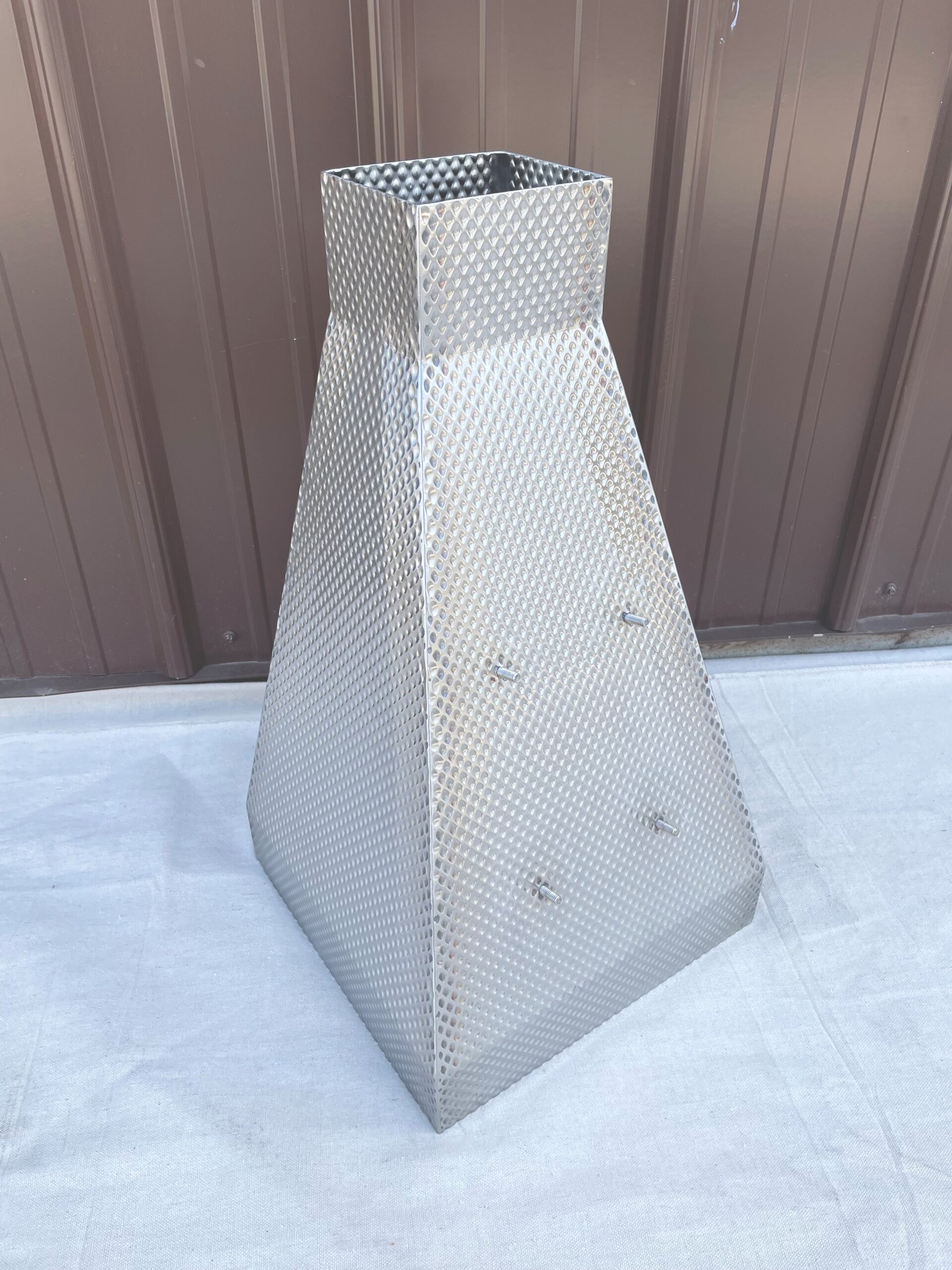

After we have laser cut your parts and formed them to exact dimensions, we will weld them in one of our 10 welding stations. Every one of our stations utilizes Weldsale Platten welding tables and various clamps to hold your product flat and to the correct size before welding. We have outfitted every station with a Tig and Mig welding source and Torit supplied dust collection to keep our workers safe. Our 5 ton overhead bridge crane will pick up the large parts and flip them as needed to give the best possible position to perform a quality weld. After welding, we will grind flat or perform polishing if needed with our vast selection of Dynabrade tools. All of our welders take great pride in putting all of the pieces together to give our customers the finished products they are looking for.